Tightening torques

At Archey, we understand the importance of correct tightening torques, also known as torques, for both dry and lubricated joints. This force, expressed in Newton meters (Nm), is critical to achieving the correct clamping force in a joint.

Support from Archey

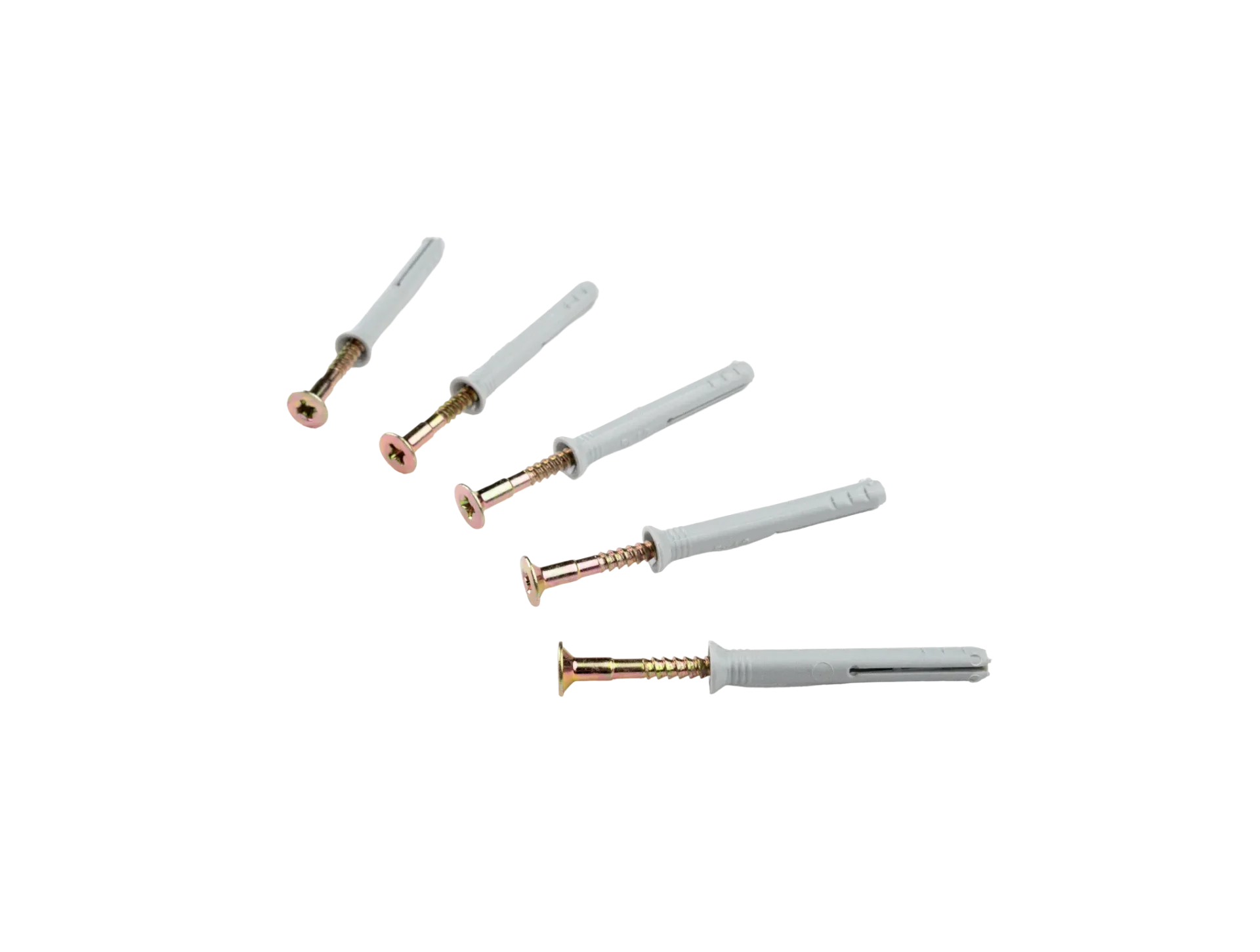

Whether you are working with waxed, oiled or uncoated screws, choosing the correct tightening torque is essential. In lubricated joints, where screws are often coated, the coefficient of friction for the thread (µthread) and the bearing surface (µhead) is between 0.100 and 0.125. This means that less force is required to properly tighten the screw, allowing you to achieve optimum clamping force.

With dry joints, such as untreated or aged screws, the coefficient of friction is higher, around 0.140. As a result, more force is required to overcome the friction and the tightening torque remains higher to ensure sufficient clamping force.

Our Tightening Torques

Tightening torque plays an important role in many industrial sectors where joints must continue to perform under high pressure. For stainless steel screws, for example, the tightening torque must usually be specified by the screw supplier. If this information is not available, the tightening torque of a 6.8 grade steel screw (according to DIN267) is often taken as a reference.

Support from Archey

Choose Archey and discover how our advanced solutions can help you fully integrate your manufacturing processes with the technology of the future.