Invisible protection, maximum performance: the crucial role of coatings in fastening technology

In extreme conditions, a bolt or nut is only truly reliable when it is protected by an invisible hero: the coating. Coating technology is playing an increasing role within fastening technology, especially in markets where chemicals, moisture, salt or heat are the greatest enemies. Think offshore wind farms, petrochemical plants or high-tech manufacturing environments. At Archey, we see coatings not as an add-on, but as an essential part of the solution.

Medium length heading with extra lenght for good measure

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Cupiditate quod praesentium exercitationem distinctio, porro doloremque ab. Id tempore quas doloremque voluptas quis?

Coatings: more than a coat of paint

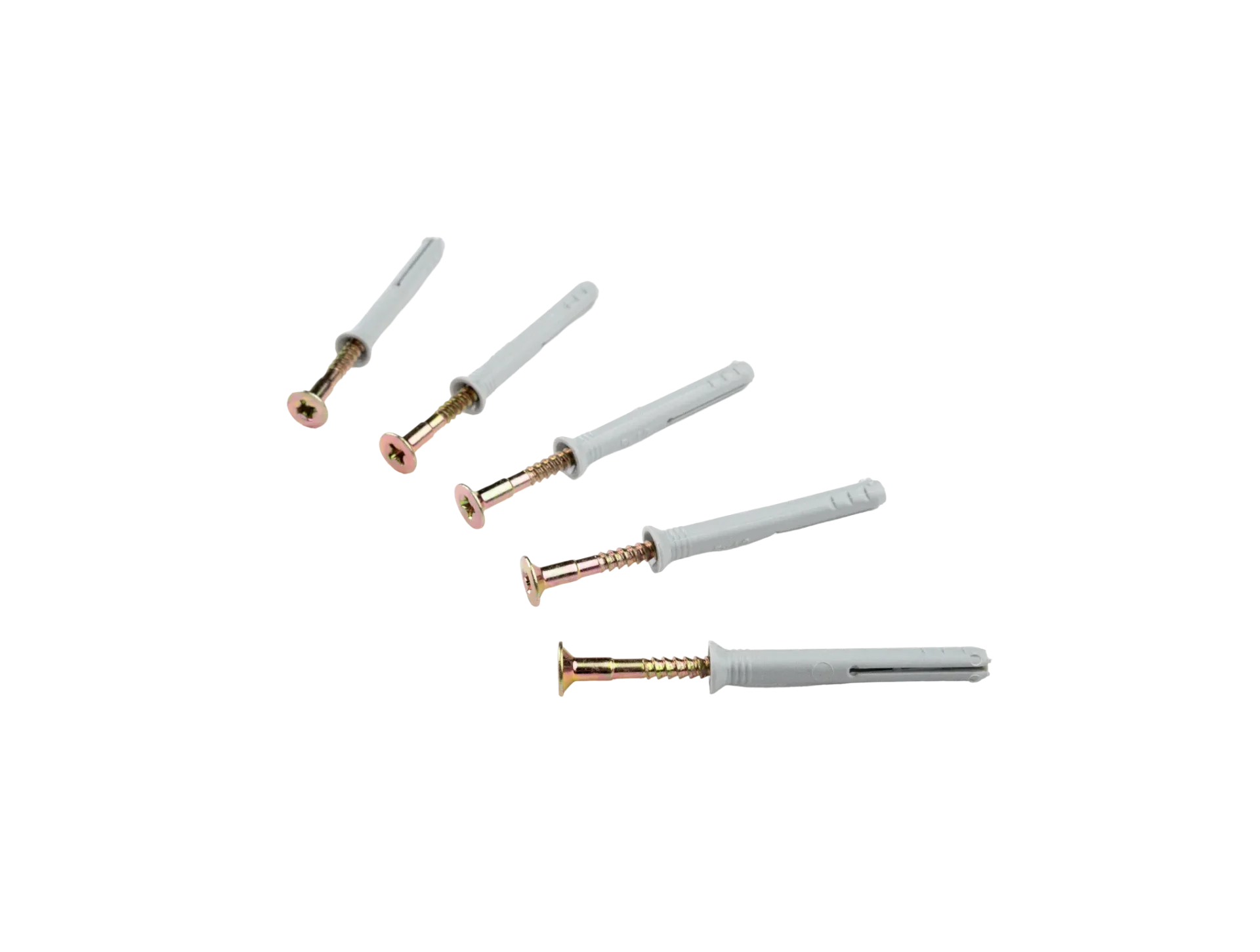

The core function of a coating? Corrosion protection. Modern systems such as Xylan or Xylar+Xylan can withstand up to 4,000 hours of salt spray testing - a performance that far surpasses base materials such as stainless steel or steel. The coating forms a chemical barrier as well as preventing moisture infiltration, significantly extending the service life of fasteners.

In addition, PTFE-based coatings provide friction reduction. That means easier assembly, less risk of jamming (galling) and less wear - crucial for applications where regular maintenance or disassembly occurs.

Technologies with impact

Zinc coatings

From electrogalvanizing to hot-dip galvanizing, zinc protects by being the first to corrode. Zinc flake coatings (such as Delta and Geomet) offer an elegant balance between corrosion resistance and dimensional stability. With only 6-8 μm coating thickness, they achieve more than 1,000 hours of salt spray test results.

Fluoropolymer coatings

Together, Xylan and Xylar form an extremely robust coating system for chemical environments. They combine excellent sliding properties with temperature resistance up to 535°C. Applications? From cleanrooms to heavy process technology.

Thermal spraying and epoxy

In applications where extreme heat, abrasion or impact play a role - such as offshore or petrochemicals - ceramic or zinc phosphate epoxy systems offer a solution. These comply with ISO 12944 (corrosion class C5-CX) and withstand the harshest conditions.

Selection criteria: the right choice starts with the application

Every coating solution begins with an analysis of the environment:

- Temperature loading - how far is the material allowed to heat up?

- Chemical influences - acids, alkalis, solvents?

- Mechanical stress - impact, vibration, abrasion?

- Corrosion class - from light (C1) to extreme (C5+)

Our specilists advise based on your application and taking into account tolerances. Because too thick a coating can cause mounting problems, while poor adhesion or porosity leads to localized corrosion.

From inspection to life extension

A coating stands or falls with its application. Therefore, monitoring during the application process is essential: humidity, dew point, surface temperature - everything must be right. After that, inspections and preventive maintenance take over. Early detection of discoloration, blistering or flaking extends the service life and prevents downtime.

Future-proof coating

The market is moving towards sustainable and smart coatings: chromium(VI)-free systems, water-based solutions and even self-repairing nanocoatings. Archey follows these innovations closely - not because it has to, but because it contributes to reliability, safety and circularity.

At Archey, we consider coating technology an integral part of fastening technology. Our role does not stop with supplying the right fastener - we make sure that that fastener continues to perform, even under the harshest conditions. With knowledge, partnership and precision.

Want to know more about coatings for your project?

Ask Archey. We think with you, from selection to service.

Medium length heading with extra lenght for good measure

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Cupiditate quod praesentium exercitationem distinctio, porro doloremque ab. Id tempore quas doloremque voluptas quis?

Consectetur pharetra tempus lacus et. Aliquet massa commodo pharetra nulla rhoncus habitasse sed sit. Tortor enim dictum malesuada nunc nulla sed arcu vestibulum in. Vitae at tincidunt tellus pharetra ac augue lobortis phasellus. Porttitor adipiscing lobortis duis gravida posuere. Nec non tincidunt tempus ornare ut senectus tristique nec porta. Purus sit ullamcorper id rhoncus massa. Sed vel sodales in sit scelerisque sollicitudin nisl. Massa viverra euismod lectus porttitor ornare dis platea volutpat. Facilisi ante ullamcorper nibh leo. Vulputate porttitor sit nisi elementum sem. Orci semper orci orci cras.

Medium length heading with extra lenght for good measure

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Cupiditate quod praesentium exercitationem distinctio, porro doloremque ab. Id tempore quas doloremque voluptas quis?

Latest insights

At Archey, we are challenged multiple times on issues where our high-quality fasteners play a decisive role. We prefer to share those challenges with the whole world.

February 24, 2024