The influence of vibration and temperature on the performance of fasteners

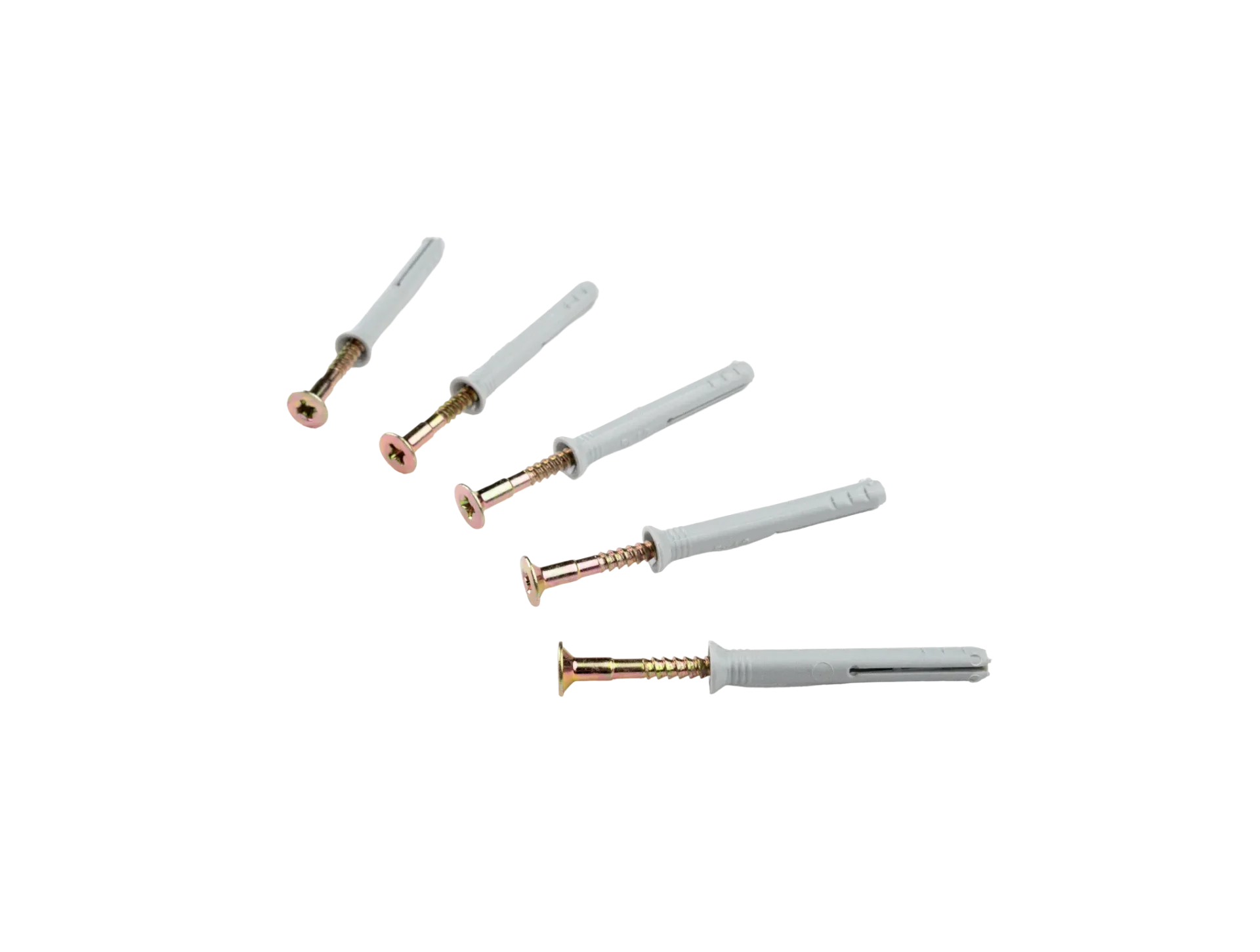

Fasteners appear at first glance to be simple components, but their performance is greatly affected by the environment in which they are applied. In sectors such as infrastructure, offshore, energy, mechanical engineering and transportation, fasteners are exposed to extreme conditions on a daily basis.

Medium length heading with extra lenght for good measure

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Cupiditate quod praesentium exercitationem distinctio, porro doloremque ab. Id tempore quas doloremque voluptas quis?

Vibration and temperature changes can strain the reliability of a fastener - resulting in wear, loosening or even structural failure. In this article, we dive deeper into how these factors work AND what you can do to maintain fastener performance.

How vibrations affect fasteners

Vibrations create repetitive, dynamic stresses on joints. Even minute movements can cause a bolt or nut to loosen slowly.

Main effects:

- Reduced preload: small vibrations reduce the clamping force, loosening the joint.

- Fatigue of material: repeated loading creates micro-cracks that lead to fracture.

- Fretting corrosion: friction between surfaces causes wear and oxidation.

Typical risk applications:

- Bridges, rail structures and heavy machinery.

- Offshore installations and wind turbines.

- Engine blocks, compressors and pumps.

Anti-vibration solutions:

- Self-locking nuts or washers (such as Heico-Lock lock washers).

- Use proper tightening torque - too low or too high causes instability.

- Precision control during assembly and periodic inspection.

The influence of temperature on compounds

Temperature changes cause expansion and contraction in materials. In metal components, this can lead to changes in tension and clamping force.

Main effects:

- Thermal expansion: at high temperatures, materials expand, which can cause joints to loosen.

- Thermal fatigue: repeated fluctuations weaken the material at the microscopic level.

- Different coefficients of expansion: stress differences occur in combinations of steel, aluminum or composites.

Sectors with high temperature influences:

- Petrochemical plants.

- Power plants.

- Solar panel and heat systems.

- Aviation and Defense.

Solutions against temperature effects:

- Heat-resistant alloys such as Inconel

- Coatings that prevent oxidation and corrosion in heat.

- Use of appropriate seals and insulating rings in temperature-sensitive applications.

- Design with strain compensation to accommodate thermal deformation.

Why combining both factors is crucial

In many environments - think offshore wind turbines or engine installations - vibrations as well as temperature changes work together.

The combination results in faster preload degradation, fatigue of materials and a higher risk of loosening.

It is therefore essential to take both loads into account as early as the design phase, and to choose solutions that can handle these double loads.

How Archey helps ensure performance

Archey supports customers with fastening solutions specifically designed for high load, vibration and temperature change environments. Archey does this by:

- Advice on material and coating selection based on application and environment.

- Use of certified, vibration-resistant systems.

- Co-engineering with engineers to optimize connections for specific projects.

- Quality assurance and traceability to ensure performance and reliability.

Conclusion

Vibration and temperature are unavoidable factors in many engineering applications, but with the right knowledge and choice of materials, risks can be drastically reduced.

Smart engineering and reliable fastening solutions ensure stable, safe and durable connections - even under extreme conditions.

With Archey as a partner, customers have both the right expertise and products to make any connection withstand the force of vibration and temperature.

Medium length heading with extra lenght for good measure

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Cupiditate quod praesentium exercitationem distinctio, porro doloremque ab. Id tempore quas doloremque voluptas quis?

Consectetur pharetra tempus lacus et. Aliquet massa commodo pharetra nulla rhoncus habitasse sed sit. Tortor enim dictum malesuada nunc nulla sed arcu vestibulum in. Vitae at tincidunt tellus pharetra ac augue lobortis phasellus. Porttitor adipiscing lobortis duis gravida posuere. Nec non tincidunt tempus ornare ut senectus tristique nec porta. Purus sit ullamcorper id rhoncus massa. Sed vel sodales in sit scelerisque sollicitudin nisl. Massa viverra euismod lectus porttitor ornare dis platea volutpat. Facilisi ante ullamcorper nibh leo. Vulputate porttitor sit nisi elementum sem. Orci semper orci orci cras.

Medium length heading with extra lenght for good measure

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Cupiditate quod praesentium exercitationem distinctio, porro doloremque ab. Id tempore quas doloremque voluptas quis?

Latest insights

At Archey, we are challenged multiple times on issues where our high-quality fasteners play a decisive role. We prefer to share those challenges with the whole world.

February 24, 2024