How to prevent quality problems caused by incorrect fasteners by choosing the right tool

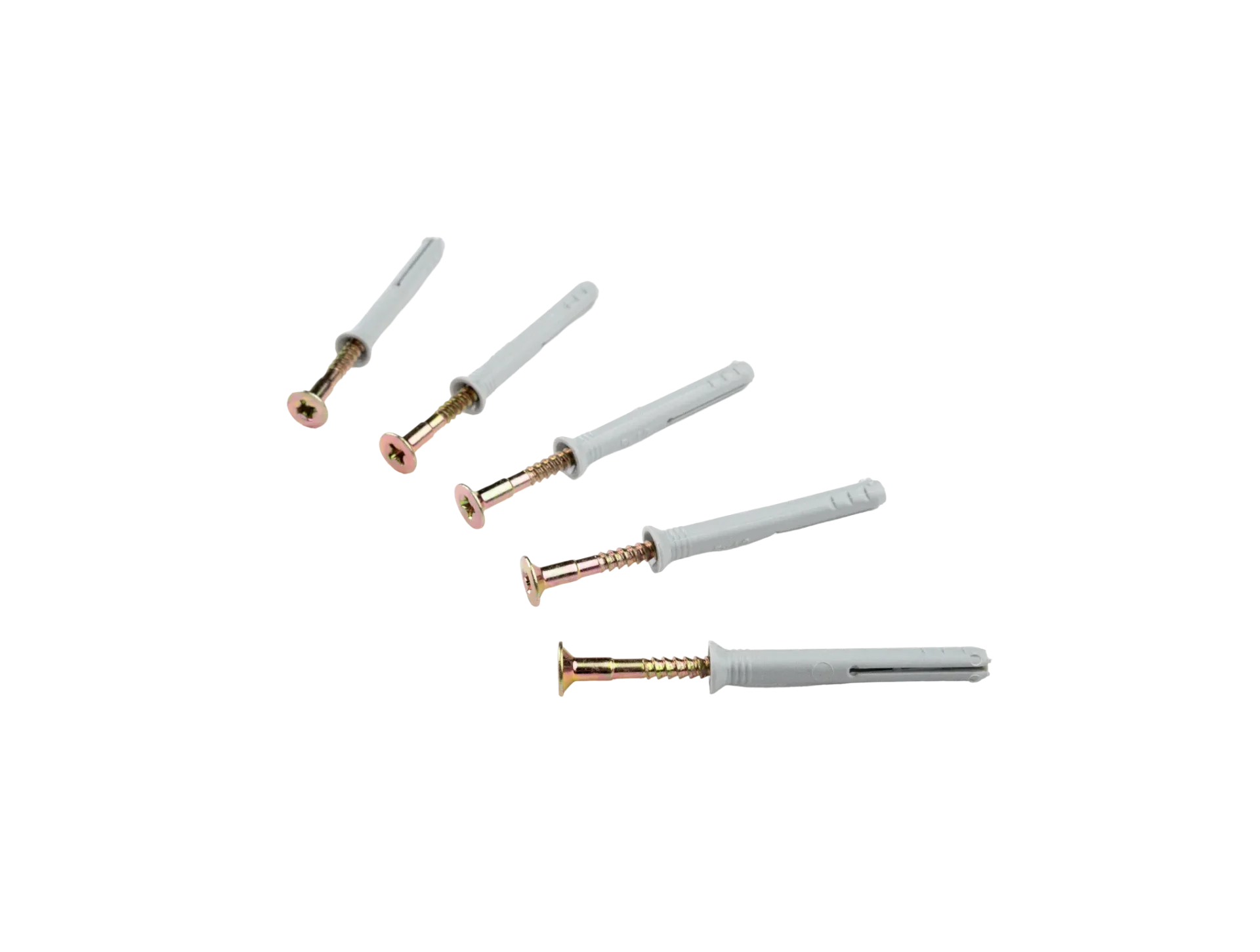

A fastener is only as good as the way it is assembled. In industrial environments where precision and safety are paramount, the wrong combination of fastener and tool can lead to quality issues, wear, or even structural failure.

Medium length heading with extra lenght for good measure

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Cupiditate quod praesentium exercitationem distinctio, porro doloremque ab. Id tempore quas doloremque voluptas quis?

Choosing the right tool, from torque wrench to power socket, is therefore essential to ensure consistency, reliability, and quality in every project.

The link between tools and fastener quality

Using incorrect or worn tools can drastically affect the performance of fasteners. Consider:

- Excessive or insufficient tightening torques, resulting in connections being too loose or too tight.

- Damaged screw heads caused by incorrect bits or caps.

- Irregular tension, leading to uneven loading of the structure.

- Wear on threaded connections due to incorrect torque or impact settings.

The result: higher failure costs, rework, and risk of downtime.

Why choosing the right tool is so important

- Consistent quality in assembly

With a correctly calibrated torque wrench or electronic torque tool, the tightening torque is achieved exactly according to specification. This ensures that connections are consistent and reproducible—a requirement in sectors such as energy, offshore, and mechanical engineering.

- Protection of materials and components

The right tools prevent fasteners or surfaces from being damaged during assembly. This keeps the corrosion protection intact and extends the service life of the connection.

- Efficiency in the workshop

Well-coordinated tools reduce assembly time and minimize human error. This translates to less repair work and lower assembly costs.

- Safety and compliance

Many projects are subject to strict standards (e.g., ISO 6789 for torque wrenches). Tools that are correctly calibrated and certified ensure compliance with these safety and quality guidelines.

Practical examples

- In an offshore project, switching from standard impact wrenches to certified torque tools reduced the number of assembly errors by 35%.

- In mechanical engineering, the right combination of bit and fastener led to less wear on components, which extended maintenance intervals.

- In energy installations, a calibrated torque wrench prevented bolt overload, thereby preventing leaks and production downtime.

How Archey helps to guarantee quality

Archey not only offers a wide range of fasteners, but also the matching tools and accessories to guarantee installation quality.

Customers benefit from:

- Calibrated torque wrenches and torque tools with certification.

- Power sockets, bits, and adapters that fit perfectly with specific fasteners.

- Customized advice on torque, tension, and tool selection for each application.

- Maintenance and calibration service to keep tools accurate and reliable.

With this integrated approach, Archey ensures that every component—from fastener to tool—contributes to maximum reliability and quality.

Conclusion

Many quality problems are not caused by the fastener itself, but by incorrect installation.

By investing in the right tools, calibration, and tool selection, companies can reduce failure costs, limit maintenance, and increase safety.

Archey combines product knowledge with practical expertise to help customers find the perfect balance between fastener, tool, and application—the basis for lasting quality in every connection.

Medium length heading with extra lenght for good measure

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Cupiditate quod praesentium exercitationem distinctio, porro doloremque ab. Id tempore quas doloremque voluptas quis?

Consectetur pharetra tempus lacus et. Aliquet massa commodo pharetra nulla rhoncus habitasse sed sit. Tortor enim dictum malesuada nunc nulla sed arcu vestibulum in. Vitae at tincidunt tellus pharetra ac augue lobortis phasellus. Porttitor adipiscing lobortis duis gravida posuere. Nec non tincidunt tempus ornare ut senectus tristique nec porta. Purus sit ullamcorper id rhoncus massa. Sed vel sodales in sit scelerisque sollicitudin nisl. Massa viverra euismod lectus porttitor ornare dis platea volutpat. Facilisi ante ullamcorper nibh leo. Vulputate porttitor sit nisi elementum sem. Orci semper orci orci cras.

Medium length heading with extra lenght for good measure

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Cupiditate quod praesentium exercitationem distinctio, porro doloremque ab. Id tempore quas doloremque voluptas quis?

Latest insights

At Archey, we are challenged multiple times on issues where our high-quality fasteners play a decisive role. We prefer to share those challenges with the whole world.

February 24, 2024