Innovations in corrosion protection: how fasteners last longer under extreme conditions

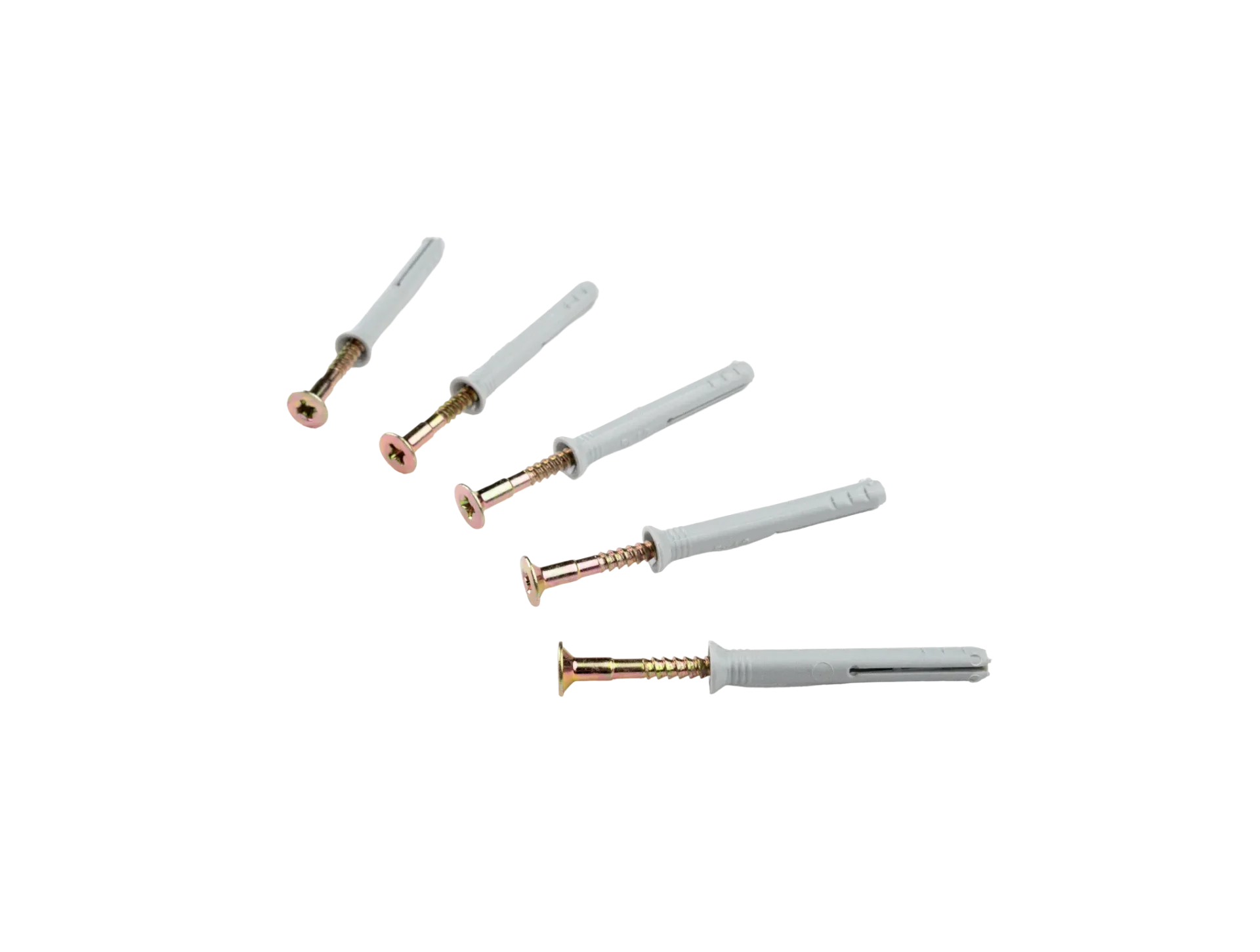

Fasteners are often the invisible heroes in structures: small in size, but crucial to the safety and durability of a project. Especially in sectors such as offshore, petrochemical, infrastructure and renewable energy, fasteners are exposed to extreme conditions. Corrosion is one of the biggest threats in this regard.

Medium length heading with extra lenght for good measure

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Cupiditate quod praesentium exercitationem distinctio, porro doloremque ab. Id tempore quas doloremque voluptas quis?

Fortunately, innovations in corrosion protection are making fasteners last longer and become more reliable.

The problem of corrosion

Corrosion occurs when metals react with their environment, such as moisture, salt and chemicals. This can lead to:

- Reduced strength and eventual joint failure.

- Higher maintenance costs due to frequent replacement.

- Risks to safety and continuity of critical facilities.

So in industries where safety and reliability are key, corrosion protection is not a luxury, but a necessity.

Innovations in coatings and materials

In recent years, many innovations have been developed to better protect fasteners:

- Advanced zinc and alloy coatings that provide long-term protection even in salty offshore environments.

- Duplex coatings that combine multiple layers for optimal resistance.

- Stainless steel (SS) and special alloys that are more resistant to aggressive chemicals.

- Nano-coatings that form an extremely thin but very strong protective layer.

These innovations significantly extend service life and reduce the need for maintenance.

Practical benefits for projects

Thanks to better corrosion protection, companies benefit from:

- Lower total cost of ownership, due to fewer replacements and maintenance.

- Higher safety by greatly reducing the probability of failure.

- Sustainability because materials last longer and waste is avoided.

- Reliability even under extreme conditions such as offshore wind farms or chemical plants.

How Archey adds value

Archey works with leading suppliers and develops its own solutions that meet the highest standards for corrosion protection. By combining knowledge of both sectors and materials, Archey can advise customers which fasteners are best suited to their application. From standard coatings to fully customized solutions: always with the aim of making projects safer, more durable and cost-efficient.

Conclusion

Corrosion may be a natural process, but its consequences are preventable. Thanks to innovations in coatings and materials, fasteners last longer, even under the harshest conditions. For companies looking for security in their critical projects, the right choice in corrosion protection is an investment in safety and durability - and with Archey, they have a partner at the forefront of this.

Medium length heading with extra lenght for good measure

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Cupiditate quod praesentium exercitationem distinctio, porro doloremque ab. Id tempore quas doloremque voluptas quis?

Consectetur pharetra tempus lacus et. Aliquet massa commodo pharetra nulla rhoncus habitasse sed sit. Tortor enim dictum malesuada nunc nulla sed arcu vestibulum in. Vitae at tincidunt tellus pharetra ac augue lobortis phasellus. Porttitor adipiscing lobortis duis gravida posuere. Nec non tincidunt tempus ornare ut senectus tristique nec porta. Purus sit ullamcorper id rhoncus massa. Sed vel sodales in sit scelerisque sollicitudin nisl. Massa viverra euismod lectus porttitor ornare dis platea volutpat. Facilisi ante ullamcorper nibh leo. Vulputate porttitor sit nisi elementum sem. Orci semper orci orci cras.

Medium length heading with extra lenght for good measure

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Cupiditate quod praesentium exercitationem distinctio, porro doloremque ab. Id tempore quas doloremque voluptas quis?

Latest insights

At Archey, we are challenged multiple times on issues where our high-quality fasteners play a decisive role. We prefer to share those challenges with the whole world.

February 24, 2024