Common mistakes in fastener selection (and how to avoid them)

In industrial environments where reliability and continuity are key, choosing the right fastener is often not as simple as it seems. Yet mistakes are made every day that lead to costly delays, maintenance or even structural damage. Archey lists the five most common mistakes and shows how they can be prevented.

Medium length heading with extra lenght for good measure

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Cupiditate quod praesentium exercitationem distinctio, porro doloremque ab. Id tempore quas doloremque voluptas quis?

- Wrong choice of material: underestimated risk factor

In many sectors, from chemicals to offshore, corrosion is a structural risk. Yet too often standard steel is still chosen, while the application demands stainless steel, duplex or a special alloy. The result: accelerated degradation, higher maintenance costs and increased safety risk.

How to prevent. Selection based on environmental data, chemical load and useful life. Includes material recommendations according to ISO, DIN and industry-specific standards.

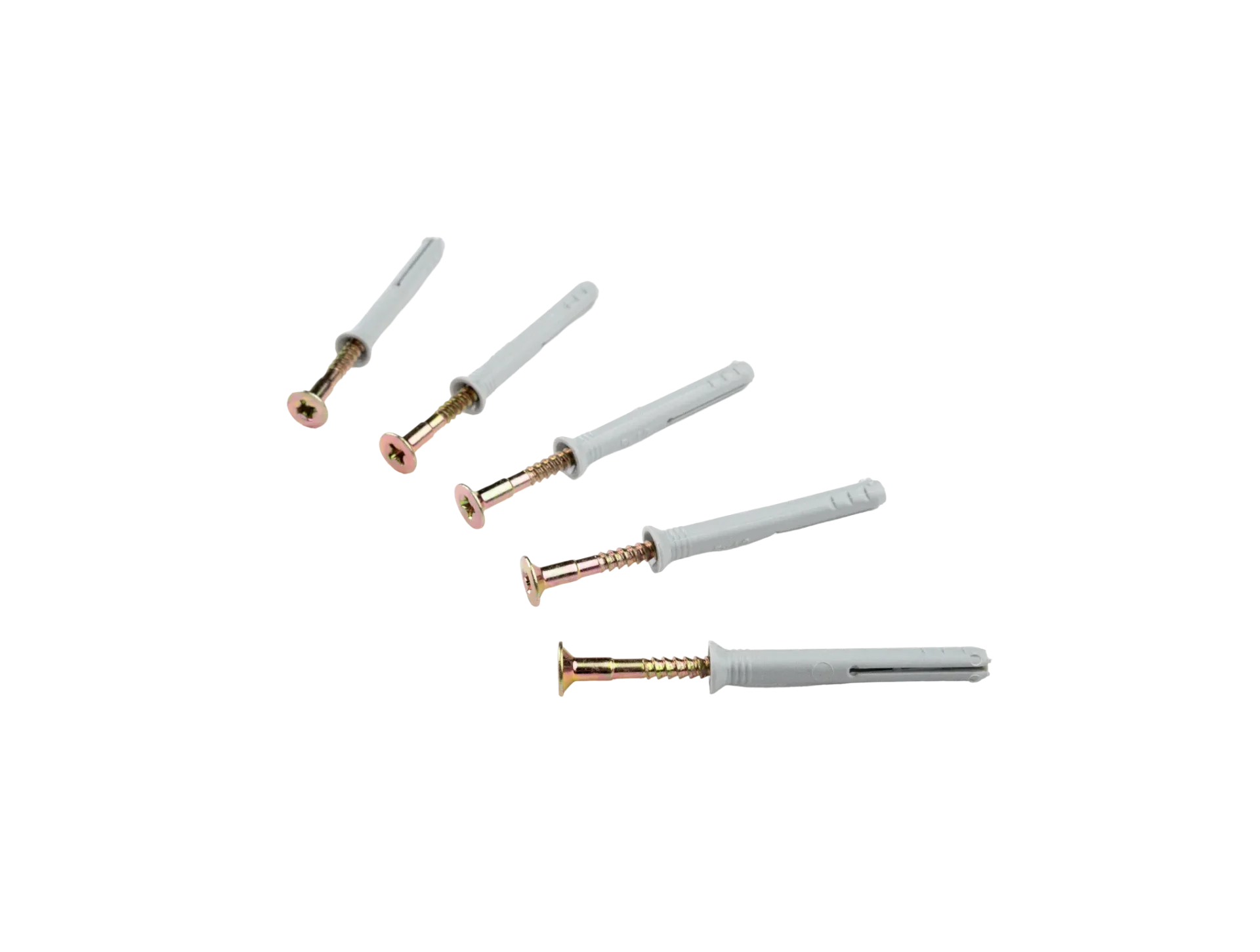

- Improper sizing or tolerance: minor deviation, major consequences

Fasteners that just don't fit lead to problems in assembly, play in construction or damage to components. In applications with dynamic loads, such as automotive or mechanical engineering, this is often disastrous.

How to avoid. Precise matching to drawing, fit, thread tolerances and any coating thicknesses. Where necessary, we provide custom or custom manufactured fasteners.

- Wrong type of fastener: standard does not always suffice

For applications with vibration, impact loads or temperature fluctuations, a standard fastener is rarely sufficient. Consider wind turbines, rail structures or heavy machinery.

How to prevent. Specialist advice based on load type, fastening method and securing requirements. Includes vibration-resistant, self-locking or HV-certified variants.

- No consideration of coating or surface treatment

Corrosion resistance often depends on the coating applied. Yet this aspect is frequently underestimated or skipped. In salty, chemical or humid environments, this can lead to premature failure.

How to prevent. Advice and supply of suitable coatings - from hot-dip galvanizing to PTFE-based systems. Always substantiated with test results (such as NSS or CASS), and tailored to the corrosion class of the application.

- Improper assembly or inadequate maintenance

Even the right fastener fails when assembled incorrectly. Too much or too little torque, use of unsuitable tools or lack of periodic maintenance leads to loosening, snagging or breakage.

How to prevent. Support in assembly instruction, torque specifications and tooling. Includes advice on tightening torques, calibration and inspection services.

Structural security begins with specialist support

At Archey, we go beyond delivery. We analyze the application, test specifications and think proactively about engineering, sourcing and maintenance. This way, you prevent errors before they occur.

Medium length heading with extra lenght for good measure

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Cupiditate quod praesentium exercitationem distinctio, porro doloremque ab. Id tempore quas doloremque voluptas quis?

Consectetur pharetra tempus lacus et. Aliquet massa commodo pharetra nulla rhoncus habitasse sed sit. Tortor enim dictum malesuada nunc nulla sed arcu vestibulum in. Vitae at tincidunt tellus pharetra ac augue lobortis phasellus. Porttitor adipiscing lobortis duis gravida posuere. Nec non tincidunt tempus ornare ut senectus tristique nec porta. Purus sit ullamcorper id rhoncus massa. Sed vel sodales in sit scelerisque sollicitudin nisl. Massa viverra euismod lectus porttitor ornare dis platea volutpat. Facilisi ante ullamcorper nibh leo. Vulputate porttitor sit nisi elementum sem. Orci semper orci orci cras.

Medium length heading with extra lenght for good measure

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Cupiditate quod praesentium exercitationem distinctio, porro doloremque ab. Id tempore quas doloremque voluptas quis?

Latest insights

At Archey, we are challenged multiple times on issues where our high-quality fasteners play a decisive role. We prefer to share those challenges with the whole world.

February 24, 2024