The WN1 specification: critical quality requirement for fasteners in defense and industry

In sectors where there is no room for error, the choice of reliable fasteners is not a matter of preference, but of necessity. Within defense applications, Krauss-Maffei Wegmann's (KMW) WN1 specification plays a key role in this. This working specification sets strict requirements for fasteners used in high-risk and demanding environments, such as military vehicles, weapon systems and infrastructure.

Medium length heading with extra lenght for good measure

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Cupiditate quod praesentium exercitationem distinctio, porro doloremque ab. Id tempore quas doloremque voluptas quis?

What is the WN1 specification?

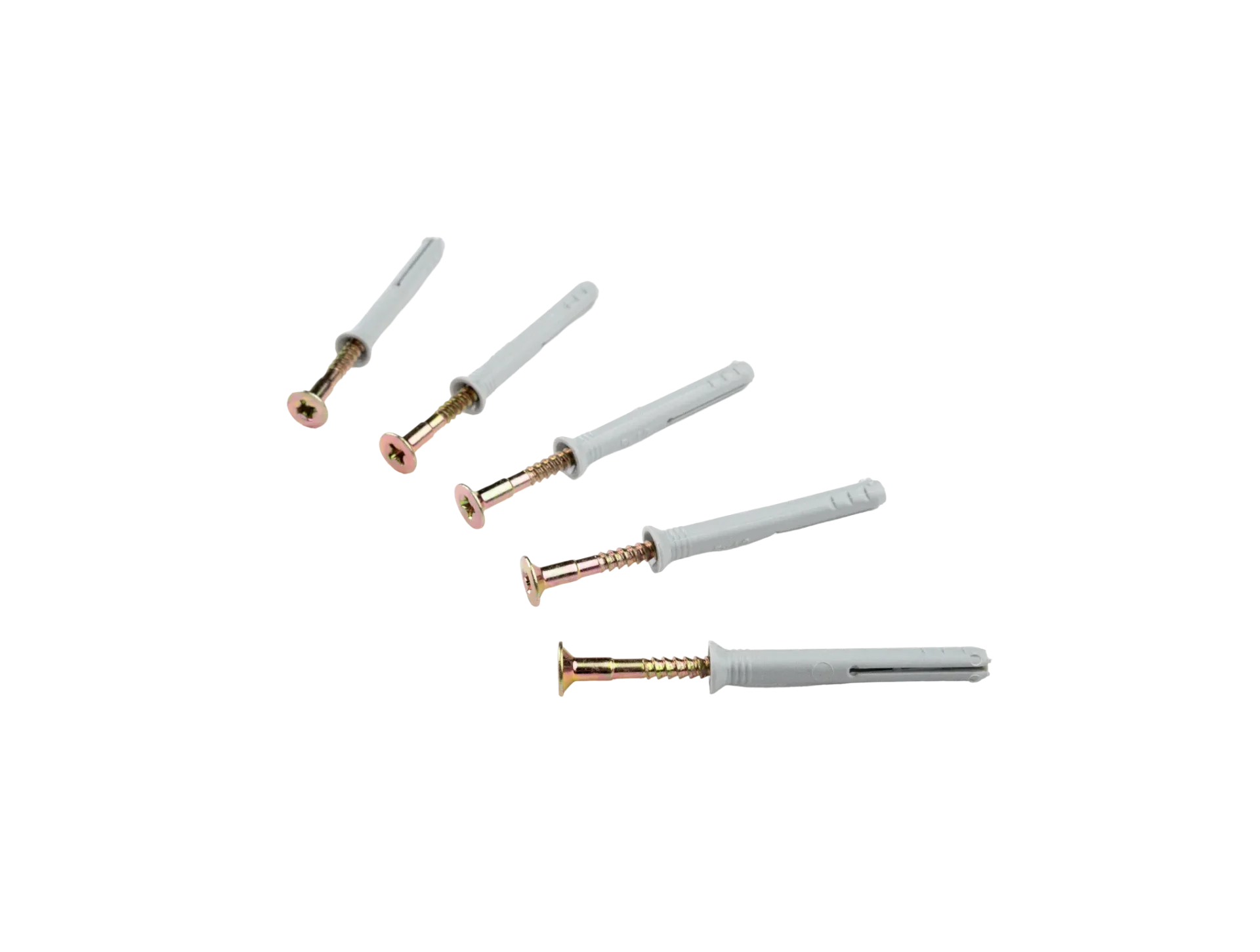

The WN1 series (WN1-1 to WN1-8) includes different coatings and quality levels for fasteners, developed as an alternative to standard standards such as DIN EN ISO 4042 and DIN EN ISO 10683. The aim is to use REACH-compliant, high-performance and corrosion-resistant finishes suitable for such items as:

- high mechanical load;

- prolonged vibrations;

- temperature fluctuations;

- and exposure to aggressive environments.

Why is WN1 important?

For applications where every connection counts, such as in the defense sector or heavily loaded industrial systems, WN1 offers assurance in terms of:

- mechanical reliability (strength classes such as 8.8 and above);

- corrosion protection (e.g., ZnNi5 or ZnNi8 coatings);

- traceability and quality assurance through defined production and testing protocols;

- REACH compliance, excluding harmful substances such as CrVI.

Technical Characteristics

Depending on the application, different WN1 codes are applied, for example:

- WN1-1: ZnNi5 coating with coefficient of friction µ0.12-0.18, suitable for fasteners up to M80.

- WN1-2: ZnNi8 coating for heavier diameters (up to M300).

- WN1-4 & WN1-5: Zinc laminates, with high or standard corrosion resistance.

- WN1-6: Light Zn3 coating, especially for fine and small wire diameters.

Each specification is linked to a clearly coded designation (such as "ISO4762-M12x100-8.8-WN1-2") that makes it immediately obvious which standard and coating applies.

Applications in practice

Although originally developed for military applications, we are increasingly seeing WN1 specifications in other industries where safety, reliability and longevity of fasteners are critical:

- Aerospace

- Offshore and shipbuilding

- Rail infrastructure

- Power plants and nuclear facilities

- Heavy mechanical engineering

What does this mean for engineers and buyers?

When fasteners are selected for critical applications, using parts to the WN1 specification provides a demonstrable guarantee of quality. Suppliers working with WN1 codes thereby demonstrate that their parts meet the toughest requirements for mechanical performance, corrosion protection and traceability.

Want to know more about fasteners according to WN1?

Contact Archey for technical advice or access to our network of suppliers working with WN1-classified fasteners.

Medium length heading with extra lenght for good measure

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Cupiditate quod praesentium exercitationem distinctio, porro doloremque ab. Id tempore quas doloremque voluptas quis?

Consectetur pharetra tempus lacus et. Aliquet massa commodo pharetra nulla rhoncus habitasse sed sit. Tortor enim dictum malesuada nunc nulla sed arcu vestibulum in. Vitae at tincidunt tellus pharetra ac augue lobortis phasellus. Porttitor adipiscing lobortis duis gravida posuere. Nec non tincidunt tempus ornare ut senectus tristique nec porta. Purus sit ullamcorper id rhoncus massa. Sed vel sodales in sit scelerisque sollicitudin nisl. Massa viverra euismod lectus porttitor ornare dis platea volutpat. Facilisi ante ullamcorper nibh leo. Vulputate porttitor sit nisi elementum sem. Orci semper orci orci cras.

Medium length heading with extra lenght for good measure

Lorem ipsum dolor sit, amet consectetur adipisicing elit. Cupiditate quod praesentium exercitationem distinctio, porro doloremque ab. Id tempore quas doloremque voluptas quis?

Latest insights

At Archey, we are challenged multiple times on issues where our high-quality fasteners play a decisive role. We prefer to share those challenges with the whole world.

February 24, 2024